Uncategorized

Alnico Magnet Crafting(Sintering & Casting): How it shapes your guitar’s voice

Magnets, those little powerhouses hidden within your beloved guitar, play a crucial role in shaping the voice of your instrument. But have you ever wondered how these silent forces come to life and how their very creation influences the music they help produce? Let’s dive into the fascinating world of magnet manufacturing and explore how different processes can orchestrate a symphony of sound!

The Birth of a Magnet:

There are two main Crafting methods for the magnets found in guitar pickups:Sintering and Casting.

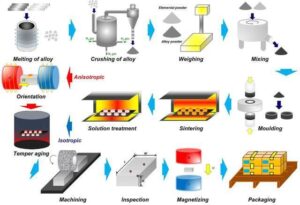

The Art of Sintering: Crafting Powerful Guitar Pickups with Alnico Magnets

Sintered alnico magnets are renowned for their exceptional musicality, gracing the pickups of countless iconic guitars. But what lies behind the magic? Let’s delve into the fascinating process that transforms raw materials into tone-shaping powerhouses.

Step 1: Grinding Alchemy

The journey begins with the meticulously chosen elements – typically aluminum, nickel, cobalt, and sometimes other metals. These are pulverized into fine powder, resembling a metallic dust shimmering with potential.

Step 2: Shaping the Dream

The powdered blend is then precisely weighed and compacted under immense pressure into a mold resembling the desired magnet shape. Imagine this as sculpting sound itself, taking form under tons of force.

Step 3: The Fiery Embrace

Next comes the transformative power of heat. The compacted form is placed in a furnace and bathed in temperatures exceeding 1200°C. Here, the individual particles sinter together, forging an unbreakable bond that defines the magnet’s core.

Step 4: Cooling the Beast

The fiery journey culminates in a controlled cool-down. The slow descent in temperature can be further influenced by an external magnetic field, determining the magnet’s final magnetic orientation and influencing its sonic character.

Step 5: Awakening the Voice

Once cooled, the rough magnet undergoes precise machining and grinding to achieve its final dimensions and smooth finish. Finally, it’s magnetized, imbuing it with the invisible force that will resonate with your guitar strings and sing through your amp.

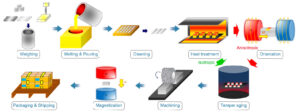

Casting a Spell: Bringing Alnico Magnets to Life through Molten Metal

Unlike their sintered counterparts, cast alnico magnets emerge from a fiery crucible, each a testament to the raw power and unpredictable beauty of molten metal. Let’s dive into the heart of the foundry and witness the transformation from fiery liquid to sonic powerhouse.

Step 1: The Crucible’s Embrace

The journey begins in a furnace, where the carefully chosen alnico alloy – a blend of aluminum, nickel, cobalt, and often other elements – melts into a shimmering pool of molten metal, glowing with molten potential. Think fiery dragons and enchanted forges!

Step 2: Shaping the Song

The molten alnico is then carefully poured into a mold crafted to the desired magnet shape. This mold acts as a musical score, guiding the liquid metal into the form that will eventually shape the sound. Precision and timing are key, for even a slight tremor can affect the final outcome.

Step 3: Solidifying the Melody

As the metal cools within the mold, it transforms from a fiery river into a solid structure, the raw power solidifying into a latent magnetic potential. Imagine the sizzling and crackle as the heat dissipates, revealing the rough form of the future magnet.

Step 4: Refining the Rough Diamond

Once cooled, the magnet is removed from the mold and undergoes a process of fettling. Think of this as sculpting the rough-hewn stone, removing excess material and imperfections to reveal the smooth, refined shape that will house the magnet’s sonic soul.

Step 5: Awakening the Voice

The final step involves magnetization. By exposing the magnet to a strong magnetic field, its internal structure aligns, imbuing it with the invisible force that will sing through your guitar strings. This act breathes life into the metal, transforming it from a mere object into a powerful conduit of sound.

Tuning the Magnetic Melody:

Now, the interesting part begins! The specific details of each process, from the composition of the alloy to the sintering temperature, can significantly impact the final sound of the magnet. Here are some key factors to consider:

-

Material Composition: Different alloys offer distinct sonic characteristics. Alnico magnets, for example, deliver a warm, vintage tone, while neodymium magnets provide a brighter, punchier sound.

-

Sintering Temperature: Higher sintering temperatures create stronger magnets with a more focused and articulate sound. Conversely, lower temperatures result in warmer, smoother tones.

-

Magnetic Field Strength: Stronger magnets translate to a louder output and a tighter attack. Weaker magnets produce a softer, more laid-back sound.

-

Magnetic Pole Configuration: Single-pole magnets offer a clear, bell-like tone, while dual-pole magnets produce a thicker, more complex sound.

The Sound of Science:

By understanding the intricate relationship between manufacturing processes and sonic outcomes, guitarists can make informed choices when selecting pickups. Imagine tailoring your instrument’s voice by choosing a magnet sintered at a specific temperature or crafted from a particular alloy. The possibilities for sonic exploration become endless!

Beyond the Basics:

This is just a glimpse into the captivating world of magnet manufacturing and its impact on sound. For the truly curious, further exploration awaits:

- Delve deeper into the science behind magnetic properties and how they influence tone.

- Investigate the unique sonic signatures of different magnet shapes and sizes.

- Experiment with custom-made magnets to craft your own signature sound.

Remember, the journey of sound starts with the silent hum of a magnet. So, the next time you strum your guitar, take a moment to appreciate the hidden symphony within, a testament to the magic of science and the artistry of music.

I hope this information, along with the visuals, provides a comprehensive and engaging exploration of the topic! Please let me know if you have any further questions or would like to delve deeper into specific aspects of magnet manufacturing and its impact on sound.